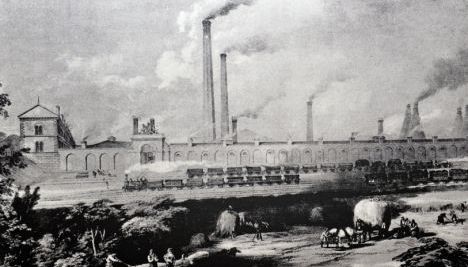

Sheffield Steelwork Industry

Sheffield And The Story Of Steel

Sheffield is a city that is synonymous with steel and for many people; the city and the metal go hand in hand. The story of Sheffield steel can be traced back to the fourteenth century, at least, with reference being made to a Sheffield Thwitel being carried by one of the pilgrims of Chaucer, but more cautious estimates suggest that the history of steel in Sheffield should only be taken back as far as 1692. There has clearly been a great evolution of steel in Sheffield since these times, but the key components which made Sheffield an industrial powerhouse over the years were all in place back then.

The availability of iron ore, enough streams to provide power and suitable stones for grinding ensured that Sheffield quickly became the steel-making centre of the UK. This developed in the 16th century, with significant progress made in the making of light steel, which helped to place Sheffield at the centre of the world for cutlery making. This was a period when a number of Flemish immigrants arrived in Sheffield, bringing knowledge and added expertise to an industry that was developing at a fair pace.

As of 1732, there were only two references to steel furnaces on local authority records and both of these furnaces were of the “cementation” style of furnace. The process was built on converting iron into blister steel, and this was performed by baking the iron in chests that were filled with charcoal. The name of the process was developed from the fact that the bars, once converted, had a blistered appearance.

Benjamin Huntsman positively impacted on steel production

A massive step on for steel production came through Benjamin Huntsman in the 1740s. Huntsman, operating in the east of Sheffield, was unhappy about the steel that was being produced but due to his knowledge of steel springs and pendulums, coupled with his mechanical background, he set about improving the steel making process.

This involved using a crucible, but there was an early setback to the new process when the cutler makers of the city refused this new type of steel, as it was too hard for them to use. Huntsman took the step of exporting his steel to France, where knives were made and then brought back to England to be sold. There was an initial outcry over this tactic, with attempts made to stop the exporting process but by 1750, a number of other Sheffield cutlers were copying his production methods and there was a boom in the local steel industry.

The good times continued into the Victorian era, and there was a further boost through the development of the Bessemer process, which occurred in the 1850s, with Henry Bessemer setting up steelworks in Sheffield. This new process helped Sheffield to stay ahead of over areas, such as Middlesbrough, which was developing a strong reputation for making iron.

The next major landmark in Sheffield steel history came at the start of the 20th century and the emergence of stainless steel. This steel was pioneered in Sheffield, around 1903, but it was being developed and worked on in the United States and Germany at the same time. This means that there are different claims on stainless steel but the long and esteemed history of Sheffield and the high quality stainless steel products that were produced in the local area means that many view Sheffield as the home of stainless steel. The size and scale of the steel production plants in Germany and the USA meant that Sheffield would eventually be usurped as the leading area for steel production, but the history of steel development still records Sheffield as an integral destination.

As well as producing steel which would be used for household items and wrought iron gates, Sheffield was also known for providing steel which helped to create the first weapons of mass destruction. As such, Sheffield steel plants were extremely busy during the First and Second World War, which also ensured that the area was bombed heavily during times of conflict.

Please login to Comments