Glass Floor Safety Standards

Engineering Safety: Load-Bearing Standards and Anti-Slip Technology for Structural Glass Floors

When installing a glass floor—whether it is an internal wine cellar hatch, a garden well cover, or a mezzanine walkway—the conversation often starts with aesthetics. However, as a direct manufacturer based in Sheffield, we know that the real "luxury" of a structural glass system isn't just how it looks, but the engineering peace of mind it provides.

To move beyond the generic advice found on reseller sites, we must look at the two critical British Standards that govern every unit we produce: BS EN 1991-1-1 and BS 7976-2.

The Math of Walk-On Glass: BS EN 1991-1-1

In the UK and Europe, structural glass floors must comply with BS EN 1991-1-1, which is the Eurocode for actions on structures. For a standard domestic application, the glass must be engineered to support a uniformly distributed load of 1.5kN per square meter and a concentrated load of 2.0kN. At Dio-Met, we utilize a minimum of 25.5mm toughened and laminated glass. This is not just about thickness; it is about redundancy. By laminating multiple layers of toughened glass together, we ensure that even in the highly unlikely event of one pane shattering, the interlayer holds the structure intact to prevent a fall with the remaining panel being calculated to take the load and maintain safety.

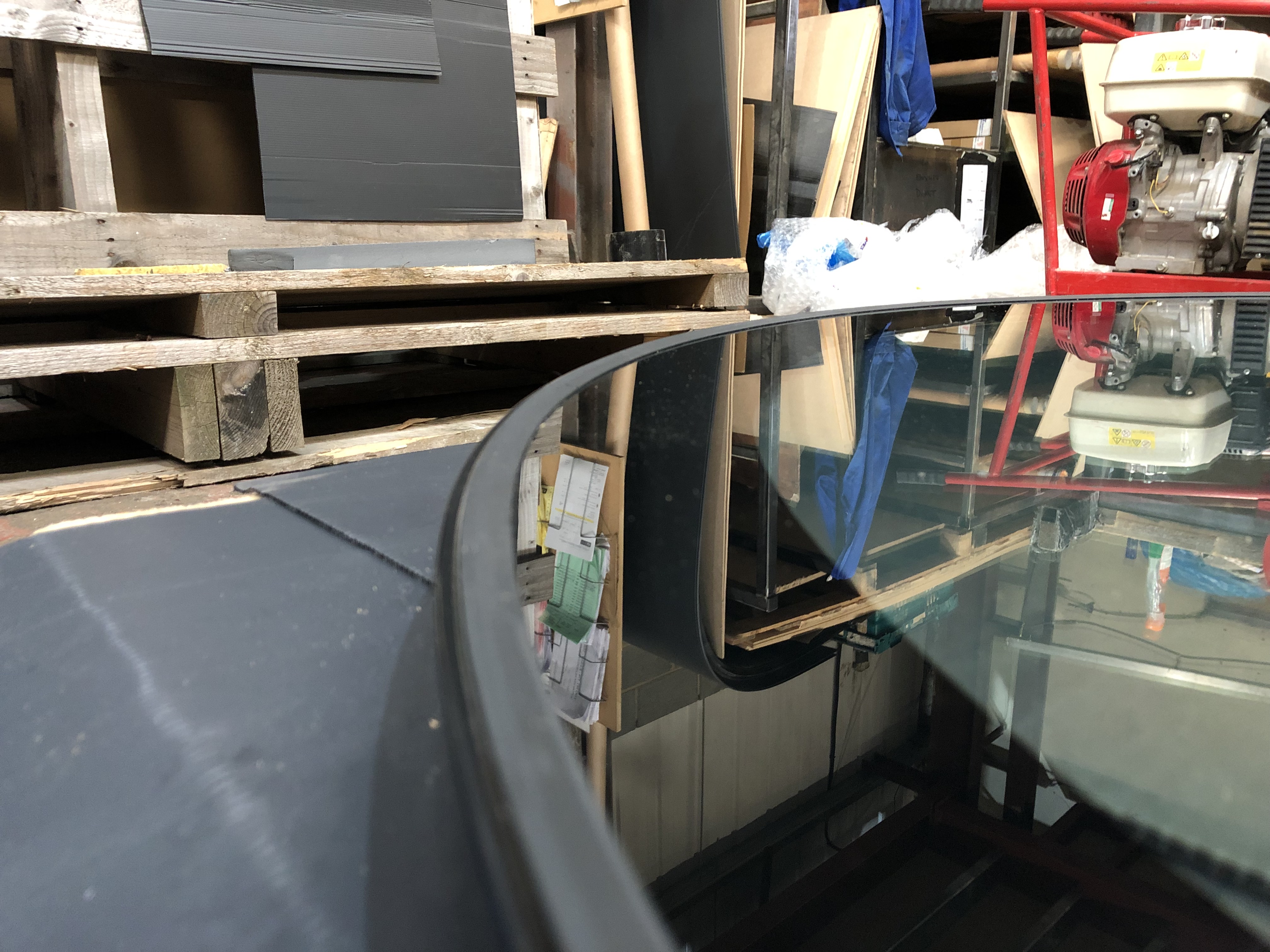

Technical Expert Insight: The 50mm black painted border shown here serves a critical engineering purpose beyond aesthetics. It masks the rubber gaskets and the slender steel support framework, ensuring a clean finish while the chemical anti-slip treatment—though invisible to the eye—provides the necessary friction for safe foot traffic. By fabricating these frames in-house to BS EN 1090 standards, we ensure the glass is supported with minimal deflection, which is vital for the long-term integrity of the walk-on system

Surface Safety: Invisible Chemical Anti-Slip Treatment

Structural integrity is only half the battle as the surface must also be safe to walk on. Under BS 7976-2, flooring is tested using a pendulum friction tester to determine its slip potential. Unlike mass-market products that use primative sandblasting or acid-etching—an old-fashioned technique that crudely dissolves the glass surface—Dio-Met utilizes a specialized mineral-based anti-slip treatment. This is not a coating that can peel off but a specialized liquid application that causes a chemical reaction with the glass. It liberates a small amount of silica which then crystallizes to create microscopic hard ridges. This creates an invisible tread that significantly increases friction without affecting the structural integrity or the crystal-clear transparency of the glass. Applied by hand in our workshop by trained operatives, this treatment lasts up to five years depending on foot traffic and can be reapplied if necessary.

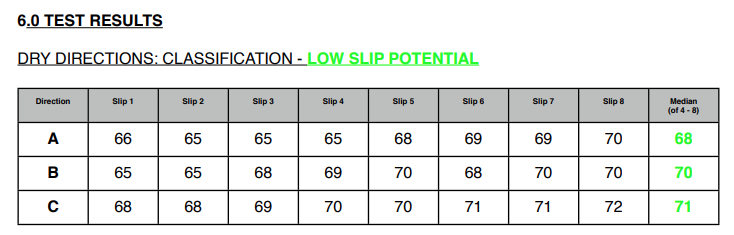

Our unique non-slip treatment achieves a PTV of 68 in dry conditions (per external testing above), far exceeding the minimum requirement of 36 to be considered low risk.

Technical Expert Insight: Why we avoid Acid-Etching

Many suppliers still use hydrofluoric acid to etch glass for grip. Not only is this process hazardous, but it works by literally eating away the product surface. Our chemical crystallization process is much gentler. By creating microscopic ridges rather than deep v-notches or pits, we maintain the full structural strength of the 25.5mm laminated pane. This is why our systems are trusted in high-traffic environments like hospitals, airports, and luxury hotels worldwide.

Application: From Basements to Gardens

We apply these rigorous standards across our entire range of structural systems. For automated wine cellar doors, which are often located in high-traffic kitchen walkways, our invisible anti-slip treatment ensures safety without ruining the view of a wine collection. For larger internal spans like walkways and floors, we engineer bespoke steel support frameworks in our Sheffield workshop to ensure the glass meets it’s deflection limits. Outdoor glass well covers face different challenges like rain and debris, so whilst our treatment improves traction when- we do recommend caution in use as the primary benefit is on dry glass. Our galvanized and powdercoated steel frames prevent corrosion in the elements.

The Manufacturer’s Guarantee

When you buy from a marketing reseller, you are often buying a kit of parts. When you source directly from Dio-Met, you are buying an engineered system. Every unit is fully assembled and pre-designed in our workshop before being crated for nationwide or worldwide delivery. This means the motor torque on electric glass doors are calibrated, the seals are factory-set for waterproofing, and the invisible anti-slip tread is applied by hand before it ever reaches your site.

Compliance Checklist for Your Project

The standard for load capacity is 1.5kN per square meter to exceed UK domestic building regulations. Our glass type is 25.5mm toughened and laminated to provide essential redundancy for fall-through protection. The slip resistance is achieved via an invisible chemical treatment for high-friction safety without loss of transparency. Furthermore, every steel framework we produce is UKCA certified to BS EN 1090. This is a mandatory legal requirement for structural integrity that many suppliers fail to meet, ensuring your installation is both safe and fully compliant. Finally, every product originates from our Sheffield workshop to ensure direct manufacturer oversight and quality control

Get in touch to request any technical drawings or see examples of our structural frame styles by calling our team on 0114 243 9009 or email sales@diometonline.co.uk

See more of our recent projects including glass well covers, wine cellar doors and structural glass.

Please login to Comments